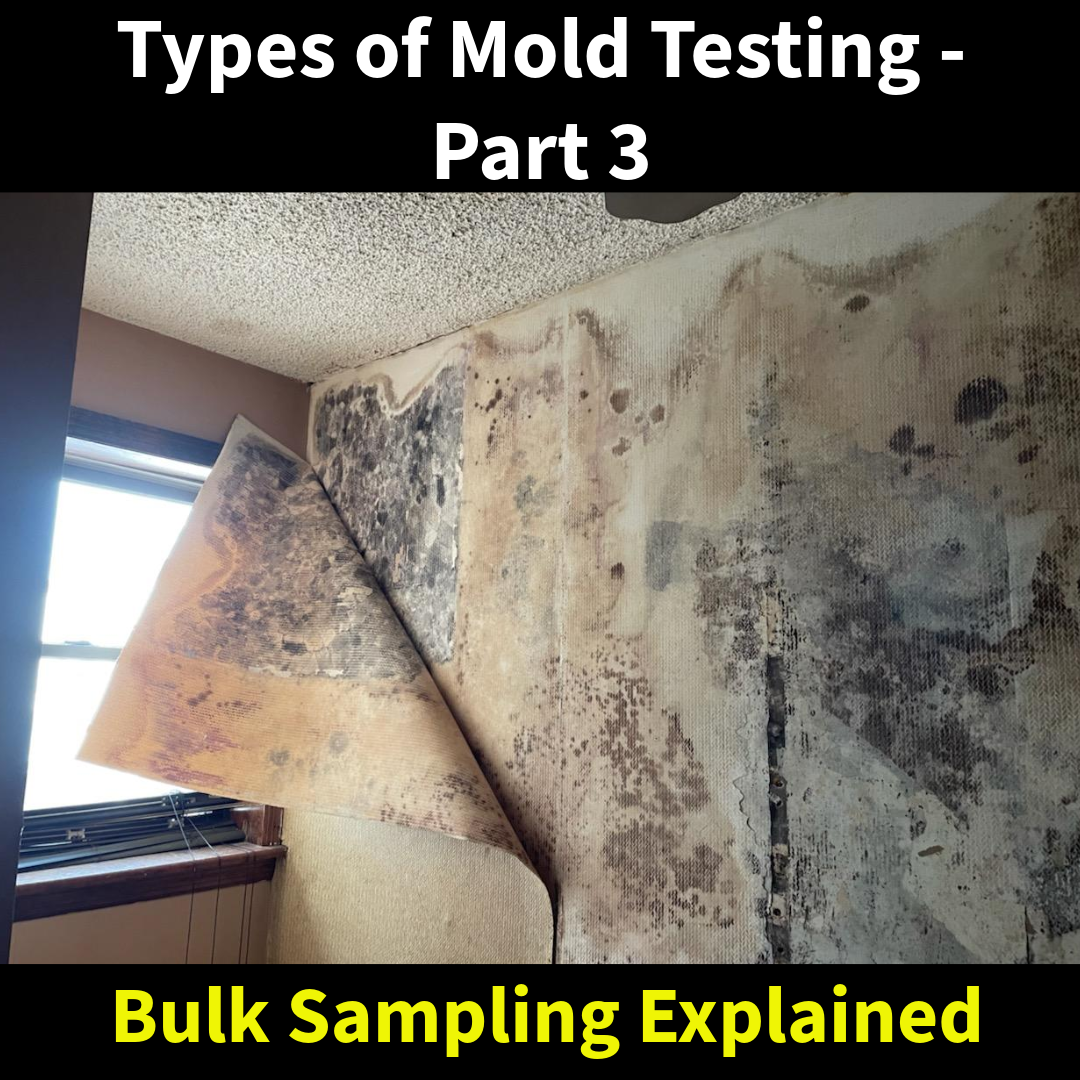

Not all mold problems grow in plain sight. Some of the most damaging infestations hide inside walls, under floors, or behind cabinets. These hidden areas stay damp long after a leak or flood, creating perfect conditions for mold growth. That’s why inspectors often use inner-wall cavity testing to confirm whether mold is present where you can’t see it.

How Cavity Testing Works

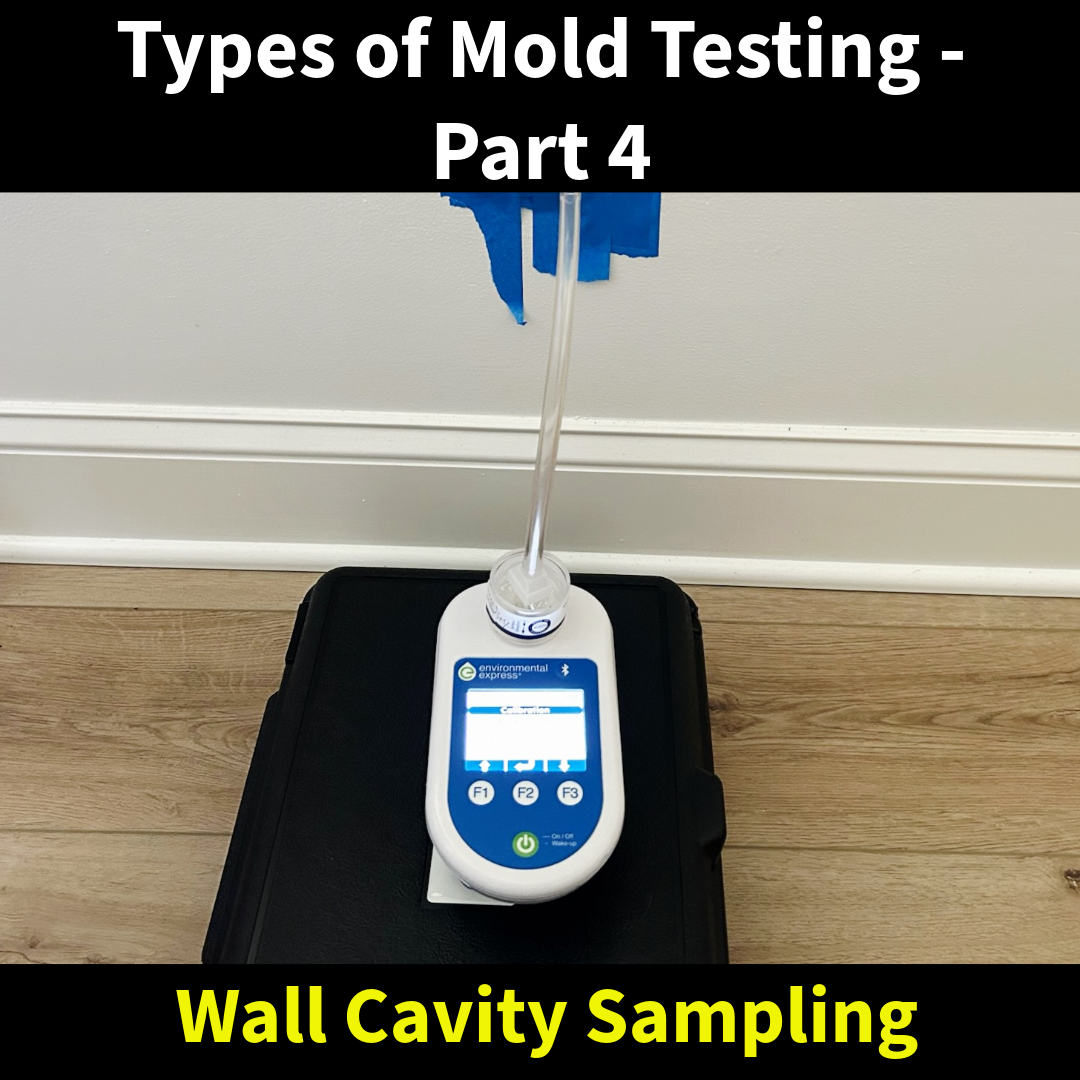

- A trained inspector drills a small, discreet hole into the wall or ceiling near the suspected area.

- A sterile tube or cassette is inserted to pull an air sample from inside the cavity.

- The sample is sent to a certified laboratory, where spore counts are compared to baseline indoor and outdoor levels.

This process gives a direct look at what’s happening behind the surface — without having to tear down entire sections of drywall.

When It’s Used

- Insurance Claim Disputes: Homeowners are often told “no visible damage, no problem.” Cavity testing can prove hidden mold exists and help validate claims.

- Follow-Up to Positive Tests: If a surface or air sample in the room already showed elevated spores, cavity testing helps confirm whether mold is also thriving behind the walls.

- Suspected Leaks: When there’s a history of plumbing issues, roof leaks, or water intrusion but no obvious staining, cavity testing can identify hidden moisture damage.

- Mystery Odors: A persistent musty smell is often the first clue that mold is active behind finished surfaces.

Why It Matters

Mold hidden inside walls can spread unchecked for months, making remediation more invasive and expensive. By detecting the problem early, inner-wall cavity testing provides homeowners with clear answers — and the documentation they need when dealing with insurance companies, landlords, or contractors.

Protect Your Property with Expert Mold Testing

If you suspect hidden mold in your home or business, don’t wait for the damage to spread. At MSI, we use industry-standard testing methods, including cavity sampling, to uncover mold where it hides and provide you with a clear plan for remediation.